Kaufman Engineering Systems KPal Compact Group of Robotic Palletizers

Small Footprint / Cost Effective Palletizing Solutions designed to palletize cases, bundles and trays.

The new Kaufman KPal compact palletizers are a perfect fit for those applications with limited floor space where an individual line requires palletizing capability. KES will configure your KPal palletizer with the most efficient end-of-arm tooling for your specific product. The KPal CV group features our proprietary vacuum-style end-of-arm tooling for conventional sealed corrugate cases. The KPal CS group features our spatula-style end-of-arm tooling for open-top cases or trays. The KPal CC group features our clamp-style end-of-arm tooling for those product arrangements which are best picked from opposing side forces. The KPal CB group features our bag end-of-arm tooling to pick and palletize sealed bags. All end-of-arm tool styles are available with the ability to pick tier sheets and/or pallets. With a long list of standard and optional features, the KPal Compact group is sure to increase the rate of return on your equipment investment.

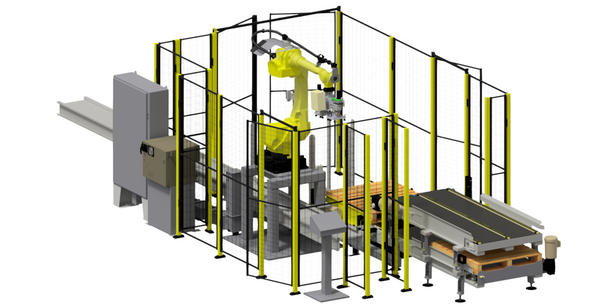

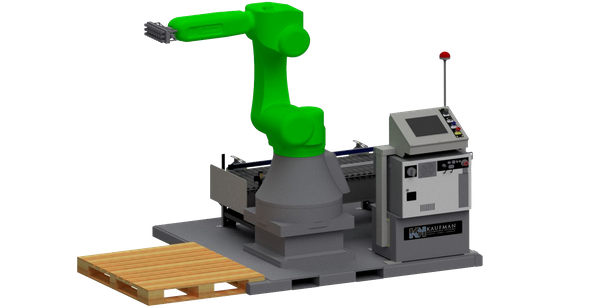

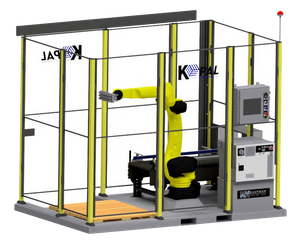

Example Configurations of KPal Compact Palletizing Systems

Compact Configuration

Compact Configuration with Conveyors

Configuration of a Collaborative, Compact System

The images above are representations of how our compact systems might be laid out. The actual configuration of each system is customized based on the unique palletizing automation needs of the customer.

Videos of KPal Compact Palletizing Systems in Action

KPal CV Small Footprint Case Palletizing System With Fenceless Loading Zone

KPal CV Small Footprint Case Conveying System

KPal Compact Palletizer Group Standard Features

KPal Compact Palletizer Group Options

Choose among a huge selection of KPal Options:

- KRL1 robotic labeler for application of labels to unit loads.

- Infeed conveyance systems and spiral conveyors to deliver products to the palletizer.

- Complete line of unit load conveying equipment including roller conveyors, chain conveyors, mattop conveyors, transfer cars, turntable conveyors, and chain transfers.

- Complete line of KES stretch wrappers.

- Ross automatic air dump valves.

- System pre-wire package with NEMA-12 wireway.

- FANUC ZDT - Zero Downtime Monitoring.

- Panel heating/air conditioning.

- Zone disconnects.

- Robot servo disconnects.

- Local motor disconnects

- Barcode scanning.

- Field installation using KES install teams.

- System start-up using KES factory-trained technicians.

- Field service by KES factory-trained technicians.

- Safety validation by Rockwell.

- UL 508A listed control panel.

Compact Robotic Palletizers Provide Answers to Workplace Labor Concerns

Kaufman Engineered Systems has designed two new standard offerings in their KPal Compact Group of palletizing systems in response to customer feedback and new interest in initiating automation since the start of the COVID pandemic. It has become a challenge for manufacturers to find and keep enough labor to fill the open positions needed. Time and time again we hear from our customers how difficult it is to find staff, have staff report on time or even report at all.

The goals of these new standard offerings are: mobility, operator friendly controls, convenient pallet pattern creation, minimal footprint, competitive price offering, and reduced lead time.

The KPal CV is a compact robotic palletizer designed using a more conventional design approach. Kaufman Engineered Systems designed this compact palletizer utilizing a FANUC M20iD / 25. The M20iD is a six-axis robot with a maximum wrist payload of 25kg or as designed, the system can support a maximum case weight of 25lbs. This robotic compact palletizer comes standard with finger safe Lexan fence panels to protect the robot operating space. Additionally, for safety, the palletizing cell is supported by FANUC DCS software which monitors and limits the operating space for the robot. Lockable main disconnect, lockable air dump, and a trapped key locking gate switch is supported by a category 3 architecture that lends to the safety of this system. The palletizer is designed to handle a 40”W x 48”L pallets as a standard. Larger sizes are available for review upon request. The end of arm tool is designed with a vacuum gripper as a base but other tools can be considered based on application. The system is supported by a fully welded support base with fork pockets for easy relocation. A zoned TGW infeed conveyor is used to bring in and control cases to the pick zone. KES rates this Palletizer for a maximum of 20 cpm using a single case pick and has designed the maximum case size at 20” x 20” x 15” with a max case weight of 25lbs. Having an overall footprint of 7.5W’ x 10’L the system takes up a minimal amount of space.

Service and Support

With each KDPal system comes Kaufman Engineered Systems service and support. Backed by 75 years serving customers, Kaufman is a partner you can rely on to respond quickly and efficiently when having service needs. With your KDPal palletizer you will have service options to choose from if you wish to setup quarterly, semi-annual, or annual maintenance support with Kaufman Qualified Technicians.

Let us help you become a new member of our family. We look forward to working with you.

Complete line of KPal Robotic Palletizing and Depalletizing solutions.

KPal Group

Robotic palletizing systems

KPal K5 Group

Full layer & bulk palletizing systems

KPal Collaborative Group

Collaborative robotic palletizing systems

Kpal Compact Group

Compact robotic palletizing systems

KPal Stack & Wrap Group

Robotic stack & wrap palletizing systems

KDPal Group

Robotic depalletizing systems

Request Quote ---- Contact Us ---- JOIN OUR MAILING LIST