Beverage, Wine & Spirits Industry: Automation to Transform Manufacturing Efficiency

Robot utilizing sweeper EOAT to move full layers of glass bottles onto conveyor.

In the dynamic world of beverage, wine, and spirits manufacturing, the steps of packaging, palletizing, securing, and depalletizing products embody a complex ballet that demands precision, efficiency, and safety. Manufacturers in this sector face considerable challenges, from maintaining high-speed production lines to ensuring the integrity and safety of bottles and packages. These challenges not only escalate operational costs but also compromise throughput and introduce significant safety hazards for workers involved in the manual handling of heavy loads and repetitive tasks.

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote

The Challenge of Traditional Processes

Traditional methods of handling and processing can lead to several inefficiencies and risks, such as:

- Increased likelihood of workplace injuries due to manual labor.

- Higher rates of product damage or loss stemming from human error.

- Bottlenecks in production lines, reducing overall throughput.

- Escalated operational costs due to inefficiencies and waste.

These issues underscore the necessity for innovation and modernization through robotic automation.

The Value of Robotic Automation

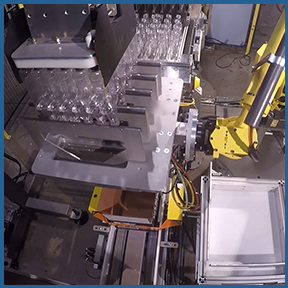

Automated system for picking and packing inverted plastic PET bottles.

Implementing automated systems within the beverage, wine, and spirits industry revolutionizes manufacturing processes, addressing the aforementioned challenges head-on. The key benefits include:

- Increased Production Efficiency: Automated systems streamline operations, from packaging to palletizing, significantly boosting production rates and ensuring consistent output around the clock.

- Enhanced Safety Standards: By replacing manual tasks with robotic solutions, the risk of injuries related to heavy lifting and repetitive motions is drastically reduced, fostering a safer work environment.

- Reduced Error Rates: Precision-engineered to perform tasks flawlessly, robotic systems minimize the chance of errors, effectively reducing loss or damage to products. This not only conserves resources but also ensures the highest quality of product reaches the market.

- Adaptability and Scalability: Modern robotic systems are designed to be flexible, easily adapting to different product types and sizes, which is particularly beneficial in an industry characterized by a wide array of packaging formats and materials.

Kaufman Engineered Systems: Your Partner in Automation

Robot with K5 sweep drawer EOAT to bulk palletize plastic water bottles.

For businesses in the beverage, wine, and spirits industry looking to overcome these manufacturing challenges, Kaufman Engineered Systems is the ideal partner. With decades of experience designing, building, and installing custom automated solutions, Kaufman understands the unique needs and intricacies of this sector.

Kaufman’s expertise includes:

· Tailored end-of-arm tooling for gentle yet efficient handling of fragile items like wine bottles and spirit containers.

· High-speed robotic palletizing and depalletizing systems that optimize warehouse space and improve logistics.

· Advanced monitoring and control systems ensure seamless integration into existing production lines, elevating both capacity and flexibility.

By choosing Kaufman Engineered Systems, businesses not only invest in cutting-edge technology but also gain a strategic advantage. We are dedicated to delivering solutions that enhance efficiency, safety, and product integrity, positioning companies for current success and setting the stage for future growth and innovation in the competitive beverage, wine, and spirits market. This empowerment is the promise of our partnership.

In conclusion, the transition to robotic automation represents a transformative step for manufacturers aiming to elevate their operations, mitigate risks, and secure a place at the forefront of the industry. With Kaufman Engineered Systems, the path to achieving these goals is clear, promising a future where efficiency, safety, and excellence are within reach, inspiring a new era of manufacturing.

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote