End-of-Line Automation Systems for BAGS

Kaufman Engineered Systems is a pioneer in designing, constructing, and executing robotic automation systems for palletizing and depalletizing bags of diverse weights and sizes. With an impressive track record extending over 75 years, Our expertise is recognized and highly sought after in the industry. Our distinction as a Level 5 FANUC Authorized System Integrator, an accolade representing the apex of ASI achievements, further underlines our authority in this field. We have a rich portfolio of bespoke systems meticulously tailored to cater to end-of-line automation for bags. These systems have consistently delivered remarkable outcomes for our customers, testifying to our commitment to innovation and efficiency.

VIEW Bag System Videos ---- Contact Us ---- Case Study ---- JOIN OUR MAILING LIST

Robotic Systems: Solving the Challenges of Packaging Bags

At Kaufman, we've had years of experience perfecting our approach to designing and constructing systems that efficiently palletize or depalletize bags for customers - but our systems go beyond the palletizing/depalletizing portion of the packaging process. We incorporate additional features into these systems to ensure that the end result is dependable and consistent. Here are a few of the additional features we've designed and built into systems to ensure the unique needs of each customer are met:

- Weight-check conveyors programmed to check for the weight specified for the bag size and reject those that are incorrect, diverting rejected bags so that the contents can be sent back to be re-bagged correctly.

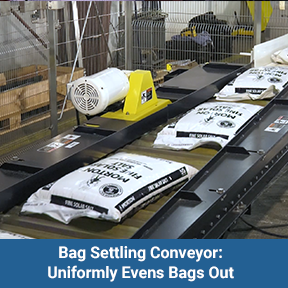

- Bag settling conveyors that agitate the bags so that contents are dispersed evenly and consistently.

- Bag flattening conveyors that squeeze bags flat rather than agitating to disperse contents and create uniform loads.

- Leak detection station where a hopper is placed under the conveyor, and there are sensors that detect when a product falls into the hopper so that leaking can then be rejected.

- Bag kicker added so that bags entering the system upright are shifted so that they lay flat.

- Stainless steel parts and chain conveyors can be incorporated to increase equipment longevity when corrosive materials are in play.

- Stretch wrapper to secure palletized bags for increased stability and to prevent bags from shifting during transit.

- Poly sheet dispenser to cover palletized bags before stretch wrapping to protect the finished load from water and dust.

- Hold down to poly sheet protective cover remains in place during the stretch wrapping process.

Videos of Bag Palletizing/Depalletizing Systems

Key Features to Look For

When considering a robotic bag palletizing solution, there are several key features that businesses should look for to ensure they are choosing the right system for their needs. These include:

- Flexibility: The ability to handle a wide range of bag sizes and weights is crucial. Look for a system that can accommodate bags weighing up to 50kg or more and can handle different types of bags such as paper, plastic, or woven materials.

- Accuracy: The system should be able to stack bags uniformly on the pallet while maintaining stability during transportation. This ensures that products arrive at their destination in perfect condition.

- Speed: A fast-paced work environment requires a system that can keep up with demand. Look for a system that can palletize bags quickly without sacrificing accuracy.

- Ease of use: Operators should be able to easily program and operate the system without extensive technical knowledge or training.

- Safety features: Robotic systems must adhere to strict safety regulations to prevent injury or damage to products. Look for features such as emergency stop buttons and sensors that detect any obstructions in the workspace.

- Reliability: The system should have minimal downtime and require little maintenance to ensure maximum productivity.

- Integration capabilities: Integrating the robotic palletizing solution with other equipment, such as conveyors or stretch wrappers, can further streamline operations and increase efficiency.

By selecting a robotic bag palletizing solution with these key features, businesses can improve their operations by increasing efficiency, reducing labor costs, and ensuring product quality and safety.

Kaufman Engineered Systems automates end of line packaging systems for multiple industries including food and paper. Click below to learn more.

Robotic End-of-Line Solutions for The Food Industry. Learn More >

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote