Transform Plastic Product Handling with Kaufman Engineered Systems

Flexibility in manufacturing and distribution of plastic products is now more than a luxury--it's a necessity. With robotic automation, the ability to customize packaging for plastic products and swiftly pivot production lines according to market demands is within your grasp. These smart systems enable a level of manufacturing flexibility that can fulfill the quest for tailored solutions and rapid innovations. The processes for palletizing, securing, and depalletizing plastic products without damage or loss come with their own set of obstacles, and robotic systems designed and built by Kaufman Engineered Systems can help you effectively address them.

VIEW Plastic System Videos ---- Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote

The Challenges

- Time and Labor Costs: Traditional methods of handling plastic products are labor-intensive and time-consuming, leading to significant operational costs. Manual packaging and palletizing not only slows down production lines but also introduces variability in performance and outcomes.

- Safety Concerns: The manual handling of plastic products, especially bulky or heavy items, poses safety risks to workers. Repetitive tasks associated with packaging and palletizing can lead to workplace injuries, further increasing costs and reducing efficiency.

- Consistency and Quality Control: Manually ensuring consistent packaging quality across large volumes of plastic products can be daunting. Variability in packaging can affect product safety during transit and ultimately impact customer satisfaction.

The Kaufman Solution

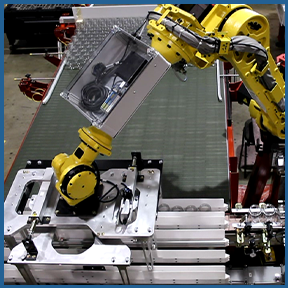

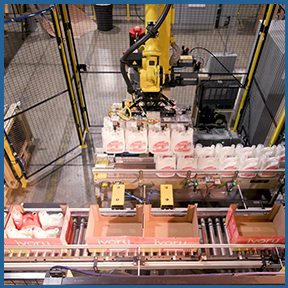

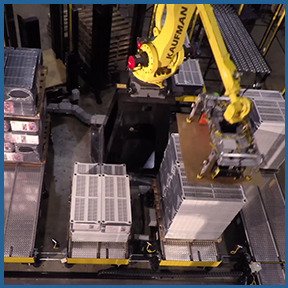

Recognizing these challenges, our team designs, builds, and installs automated systems integrated with FANUC robots and tailored end-of-arm tools that revolutionize how companies handle, palletize, secure, and depalletize plastic products. By integrating end-of-line automation systems, businesses can significantly enhance their operations in several key areas:

COST REDUCTION: Automation drastically reduces the time and labor required for packaging and palletizing processes. Our solutions are designed to operate continuously, eliminating the need for extensive manual labor and substantially lowering operational costs.

INCREASED PRODUCTIVITY: Our automated systems are not just about replacing manual labor; they're about enhancing productivity. With faster, consistent, and accurate packaging and palletizing rates, companies can achieve higher throughput, ensuring they meet demand without compromising quality.

IMPROVED SAFETY: By automating repetitive tasks, our customized systems minimize the risk of workplace injuries associated with manual handling. This not only ensures a safer work environment but also reduces the potential financial impact of worker compensation claims.

Videos for Automated Systems for Plastic Products

Why Choose Kaufman Engineered Systems?

Choosing Kaufman means more than just purchasing a piece of equipment; it's about investing in a partnership that aims to elevate your operations to new heights. Here's why Kaufman stands out:

- Expertise: With years of experience in the field, Kaufman's team possesses unparalleled knowledge in designing and implementing automation systems for the plastic industry.

- Customer Service: Kaufman prides itself on its customer service, offering comprehensive support from initial consultation through to installation and beyond.

- State-of-the-Art Technology: Kaufman utilizes the latest in automation and robotic technology, ensuring that their solutions are at the forefront of innovation.

In the competitive landscape of plastic products manufacturing and distribution, embracing automation and robotics can be the key to unlocking efficiency, safety, and cost savings. With Kaufman Engineered Systems, companies have a trusted partner ready to guide them through every step of the transformation. Discover how Kaufman's cutting-edge solutions can redefine your operations by contacting us today.

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote