Kaufman Engineering Systems KDPal Group of Robotic Depalletizers

Effective De-Palletizing Solutions designed for glass, plastic containers, cases, bundles and trays.

The new Kaufman KDPal Depalletizer Group is a perfect fit for your Depalletizing needs. For container filling applications, the system accepts a full load and efficiently creates a single stream of bottles. This family of robotic depalletizers also has the ability to singulate case, bundle, or tray loads for co-pack operations within your facility. The KDPal V depalletizer features our exclusive vacuum row pick tool for case or bundle products. The KDPal S features our spatula row pick tooling for bundle, case, or tray products. The KDPal C features our clamp row pick tooling for bundles or case products. The KDPal B depalletizer features our bag depal gripper designed to remove individual bags from a load. The KDpal K5G features our full layer end of arm tooling to accommodate glass containers and our KDPal K5P to accommodate plastic containers.

KES will configure your KDPal depalletizer with the most efficient end-of-arm tooling for your specific product. All end-of-arm tool styles are available with the ability to pick tier sheets. With a long list of standard and optional features, the KDPal Group of Depalletizers is sure to increase the rate of return on your equipment investment!

The KDPal Group of Depalletizers can be tailored to your industry segment whether it be Food, Beverage, Building Products, Paper, Plastic Container, Glass Container, Pharmaceutical, or Personal Care to name a few. KDPal Standard Features include Allen Bradley PLC and control components and Category (3) Safety Architecture, Complete system set up and testing at KES. The KDPal Depalletizer has the options to meet your plant and production needs.

The KDPal group is available in many models, including:

- KDPal V - Vacuum Depalletizing System

- KDPal S - Spatula Depalletizing System

- KDPal B - Bag Depalletizing System

- KDpal C - Clamp Depalletizing System

- KDPal K5G - Full Layer Glass Depalletizing System

- KDPal K5P - Full Layer Plastic Container Depalletizing System

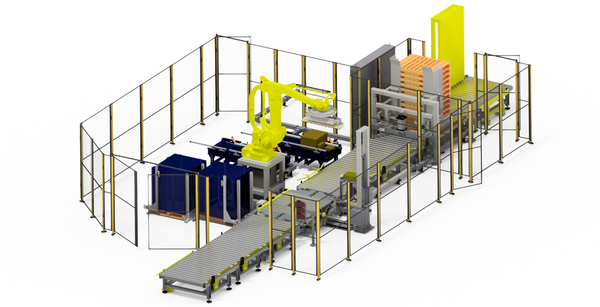

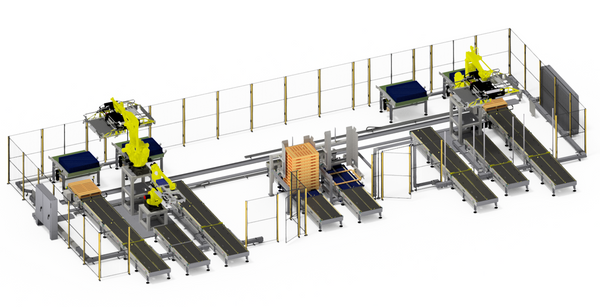

Example Configurations of KDPal Depalletizing Systems

The images above are representations of how our KDPal Depalletizing systems might be laid out. The actual configuration of each system is customized based on the unique palletizing automation needs of the customer.

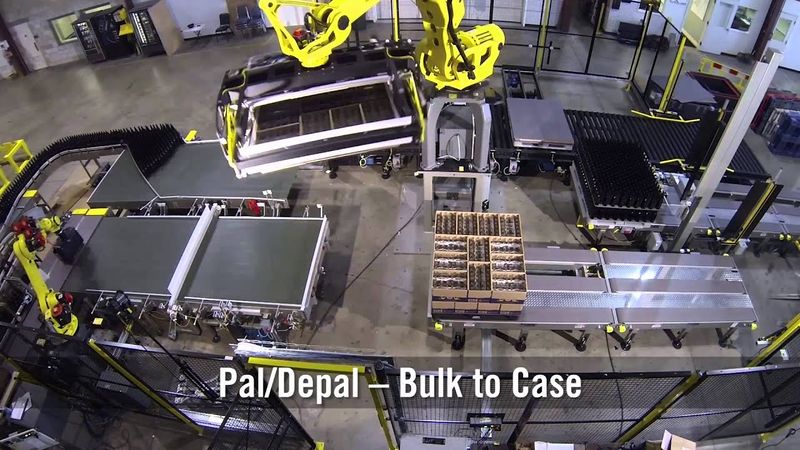

See the KDPal Depalletizing System in Action

Video Short of Depal/Pal Functionality

KPal K5G Full Layer Glass Bottle and Case Palletizing and Depalletizing Robotic System

KDal K5P Full Layer Plastic Container Depalletizer and KPal S Bundle Palletizing System

KDPal K5 Robotic Dunnage Depalletization System

KDPal Robotic Depalletizer Group Standard Features

KDPal Robodic Depalletzing Group Options

Choose among a huge selection of KDPal Options:

- KRL1 robotic labeler for application of labels to unit loads.

- Infeed conveyance systems and spiral conveyors to deliver products to the palletizer.

- Complete line of unit load conveying equipment including roller conveyors, chain conveyors, mattop conveyors, transfer cars, turntable conveyors, and chain transfers.

- Complete line of KES stretch wrappers.

- Ross automatic air dump valves.

- System pre-wire package with NEMA-12 wireway.

- FANUC ZDT - Zero Downtime Monitoring.

- Panel heating/air conditioning.

- Zone disconnects.

- Robot servo disconnects.

- Local motor disconnects

- Barcode scanning.

- Field installation using KES install teams.

- System start-up using KES factory-trained technicians.

- Field service by KES factory-trained technicians.

- Safety validation by Rockwell.

- UL 508A listed control panel.

As a level five Authorized Systems Integrator for FANUC Robotics, FANUC's highest level of attainment, Kaufman Engineered Systems applies FANUC robot technology to provide customers with complete end-of-line system solutions.

The solution may be as simple as a dedicated palletizing cell, or as complex as a multi-line handling and palletizing system. No matter how big or small, Kaufman Engineered Systems will address each project and customer with the same integrity and professional response.

Service and Support

With each KDPal system comes Kaufman Engineered Systems service and support. Backed by 75 years serving customers, Kaufman is a partner you can rely on to respond quickly and efficiently when having service needs. With your KDPal palletizer you will have service options to choose from if you wish to setup quarterly, semi-annual, or annual maintenance support with Kaufman Qualified Technicians.

Let us help you become a new member of our family. We look forward to working with you.

Complete line of KPal Robotic Palletizing and Depalletizing solutions.

KPal Group

Robotic palletizing systems

KPal K5 Group

Full layer & bulk palletizing systems

KPal Collaborative Group

Collaborative robotic palletizing systems

Kpal Compact Group

Compact robotic palletizing systems

KPal Stack & Wrap Group

Robotic stack & wrap palletizing systems

KDPal Group

Robotic depalletizing systems

Request Quote ---- Contact Us ---- JOIN OUR MAILING LIST