How to Boost Throughput Without Expanding Floor Space

Smart Automation Strategies for Facilities Requiring a Small Footprint

Growing demand doesn’t always come with growing floorspace. The good news: you can unlock significant throughput and safety gains by redesigning flows, adopting compact robotics, and using vertical conveyor solutions and simulations—without moving a single wall. Kaufman Engineered Systems (KES) helps manufacturers by designing, building, and implementing space-efficient automation that maximizes ROI, maintains RIA compliance, and improves productivity.

Request a Quote ---- Contact Us ---- JOIN OUR MAILING LIST

The Small-Footprint Challenge (and Why It's Solvable)

- Aisle and egress constraints. Industrial aisles must remain clear and provide safe clearances anywhere robotic and material handling equipment operates—so “squeezing” machines together isn’t an option. Layouts need to respect aisle markings and turning radius while preserving flow.

- Bottlenecks from uneven processes. Manual pack-out, hand palletizing, and long horizontal conveyors consume floor area and create blocking/starving.

- Changeover in tight spaces. New SKUs and pallet patterns demand agile end-of-line (EOL) equipment that can adjust quickly—without adding sprawl.

- Inventory creep. Staging Work-in-Process (WIP) and dunnage on the floor erodes every square foot, lowering effective throughput per square foot.

- Safety guarding vs. access. Traditional fences claim valuable real estate; modern fenceless and zoned solutions for applications and layouts that are truly suited to collaborative robots can reclaim that space while protecting people.

Proven Strategies to Increase Throughput in Limited Space

1. Convert to compact, multi-role palletizing cells - Modern cells combine infeed conditioning, case orientation, and robotic palletizing within surprisingly small footprints—often replacing dual manual lines with a single robot and smarter upstream flow. Compact palletizing cells can run inside areas as small as ~8’×9’ while reducing labor requirements and enabling future expansion.

KES advantage: Our KPal® Compact series uses vacuum EOAT and HMI-driven pattern software so your team can add or adjust pallet builds without reprogramming—ideal for SKU volatility and tight layouts.

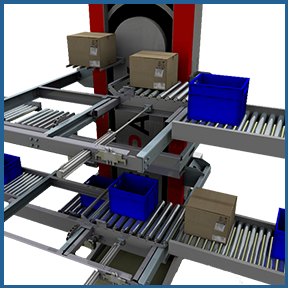

Space saving multi-level conveyance options.

2. Go vertical: accumulation, buffering, and conveyance - When you can't grow out, GROW UP. Vertical conveyors lift cases off the floor, increasing accumulation and clearing production aisles—often without the need for costly building expansions. Quick Wins:

- Use spiral/vertical conveyors for accumulation between processes instead of long horizontal runs.

- Combine AVG/LGV for dunnage/empty pallets to feed palletizers on demand.

3. Right-size and modularize conveyors -

- Shorten runs and segment by function. Swap monolithic conveyors for modular Zero Pressure Accumulation (ZPA) sections, curves, and verticals to cut footprint and improve serviceability.

- Design for maintenance access. Tight layouts still require safe clearance; smart segmentation and lift gates can preserve egress.

4. Fenceless & zoned safety to reclaim space - Safety scanners and area-rated zones (where appropriate) can reduce hard guarding while maintaining PL-rated protection, freeing space for operators and material flow. In our experience, this is viable when the space and application requirements and specifications align well with the capabilities of collaborative robots. Your KES safety design will align with applicable standards and site policies.

5. Use digital twins to "prove the fit" before you build - 3D simulation and virtual commissioning validate line capacity, queue sizes, and reach studies inside your exact footprint—de-risking concepts and accelerating FAT/SAT. Emulate3D-based projects show measurable gains by resolving sequencing and controls issues virtually.

6. Pick robots that do more from less - Selecting long-reach, high-payload arms lets one robot service multiple infeeds/pallet positions—shrinking cell count and guarding. Example: FANUC’s R-2000iC/125L pairs ~3.1 m reach with industrial payloads and tight repeatability, ideal for dense palletizing layouts. (See spec sheet for exact working envelopes during reach studies.)

What a KES Small Footprint Engagement Looks Like

1. Discovery & measurement - We capture current throughput, SKU mix, case sizes, pallet patterns, changeover frequency, and the real, laser-measured footprint—including column lines, utility drops, and keep-outs.

2. Digital fit + capacity modeling - Our engineers build a right-sized simulation (Emulate3D and related tools) to test multiple layouts, buffers, and robot reach/clearances. You see cycle times, accumulation needs, and OEE sensitivities—before committing capex.

3. Solution architecture - We propose a compact cell (often KPal® Compact), vertical conveyance, accumulation, or modular conveyor solutions where it pays back. We’ll show you the exact aisle clearances and service envelopes to ensure compliance and maintainability.

4. Build, FAT, and virtual commissioning - Our expert team utilizes your specifications and requirements to design, build, and test the system.

Where appropriate, we perform portions of commissioning virtually to compress on-site time and reduce change orders.

5. Startup and Training - Operator training, HMI pattern adjustments, and maintenance plans keep your line adaptable.

RESULTS YOU CAN EXPECT:

- More pallets/hour per square foot via single robot, multi-infeed layouts, and vertical buffers.

- Faster changeovers with HMI-editable pallet patterns (no re-programming).

- Safer aisles and access by designing clearance and guarding up front—not after install.

- Higher confidence pre-build through digital validation of fit, rate, and controls.

CASE STUDY - KES KPal® Compact: Fielded with vacuum EOAT and HMI pattern editing to adapt quickly to SKU changes—ideal when space limits duplicate lanes.

Information Needed for a High-Confidence Proposal

- Current and target pallets/hour

- SKUs (dimensions, weights, patterns)

- Available footprint with column grid & ceiling height

- Aisle, egress, and access requirements (site rules)

- Upstream/downstream equipment and utilities (air, power, network)

Why Kaufman Engineered Systems

Effectively implementing automation within a small footprint presents unique challenges—and we have the expertise to ensure your success. Kaufman Engineered Systems provides:

- Expert consultation and simulation tools like Emulate3D and RoboGuide to model your options before investing.

- Decades of industry experience in food, beverage, paper, health & beauty, building material, plastic, and glass manufacturing.

- Proprietary HMI tools for pattern changes without code

- Safety-first layouts that respect OSHA aisle and access expectations from day one

Request a Quote ---- Contact Us ---- JOIN OUR MAILING LIST