KPal-B Robotic Bag Palletizing System

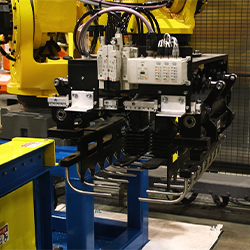

Our customer required a robotic palletizing system that could withstand a highly corrosive environment and operate efficiently at high speeds to accommodate their palletizing requirements. With our years of experience in building these types of bag palletizers, Kaufman was able to deliver. Learn more in the case study below. This system was built utilizing a FANUC 410iB 140H Robot.

To get information on what Kaufman Engineered Systems can do for you, contact us today!

THE CHALLENGE:

The customer for this project manufactures and distributes bags of salt, which creates a highly corrosive environment. The bag palletizing system they were looking to build would have to withstand the corrosive conditions and operate efficiently and accurately at high speeds.

The customer's current line uses a double-spout bagger system, which dramatically increases the number of bags coming down the line compared to a single-spout bagger system. We needed to build a system that would optimize the orientation of the robot to where it picks the bag up and where it places the bag on the pallet to obtain optimal speed that would meet their 22+ bag per minute requirement.

THE SOLUTION:

The bag palletizing system we designed and built for this customer can dispense two types of pallets: CHEP (Commonwealth Handling Equipment Pool) pallets or GMA (Grocery Manufacturer's Association) pallets. Workers at the facility use a forklift to bring a stack of pallets (typically 15 pallets at a time) and load it into the system's pallet magazine. The system will then automatically dispense the pallets onto a special conveyor one at a time and send them to the palletizing station after also placing a fiberboard sheet on the pallet to protect the bags from nails or splinters. There are scanners in place to protect the forklift operator or other personnel so that when they come into range, the system will stop working. Once they back away, the dispenser will re-engage automatically and begin running again.

The system is designed with a lot of corrosion protection measures in place to protect it from a salty, humid environment. Kaufman has gained a lot of expertise over the years in defining the sweet spot for implementing exotic corrosion protection measures to protect equipment without going so far as to impede the effectiveness of the system or become cost prohibitive. This particular system is a combination of using stainless steel where it makes the most sense but then using regular steel painted with epoxy paint to provide good corrosion protection everywhere else. The system also utilizes plastic junction boxes, non-metallic grommets for all electrical fittings, stainless steel electrical enclosures, stainless steel air conditioner, stainless steel level feed, and specially coated chain in order to minimize corrosion... all these measures are to protect the system so it lasts longer and runs well in spite of the harsh environment.

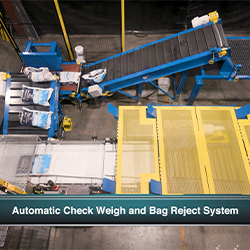

After bags are filled with product by a double-spout bagging system, they come to the Kaufman system containing product and sealed but standing upright. As it enters the system, it gets pushed to the horizontal position and wheeled to face the correct way (this part of the system is called a “Knock down conveyor”). At this point, the bag is flat, but the material inside is bunched up to the side that was the bottom in the vertical position. So next, it goes through a conditioning conveyor, which is a roller conveyor with square rollers that will gyrate the bags to get all the contents spread evenly to produce flat bags. Then it goes into a third party’s weight checker conveyor and bag reject system. If the bag is within the specified weight allowed for the 25 lb, 40 lb, 44 lb, or 50 lb bags, it will be allowed to run through to the palletizing station; if a bag is NOT in the specified weight range allowed, it will be pushed off the system onto a conveyor that will send rejected bags along to a “Re-work station” where an operator can cut them open and dump the contents so that the contents can go back to the beginning of the bagging process.

Our years of experience designing and building this type of system allowed us to optimize the robot's placement and palletizing patterns based on the size and weight of bags being palletized so that we could meet the 22+ bag-per-minute palletizing requirement.

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote