System depalletizes load, removes and stores cooling veins, and re-palletizes load in the correct order.

KPal Robotic Depalletizing with Cooling Vein Removal and Re-palletizing

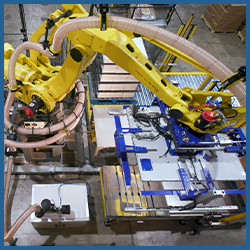

Kaufman built the custom robotic depalletizing and palletizing system featured in the case study below, utilizing a FANUC M-410iB/700 robot. The system was designed and built with the customer's specific requirements in mind. Check out the video and detailed information on this page to learn about the customer's unique challenges and the system we designed, built, and installed to overcome those challenges.

Contact us today to get information on what Kaufman Engineered Systems can do for you!

CUSTOMER OVERVIEW:

A major food processing company approached us about solving issues in the packaging and cooling process. Their operation required efficient cooling of palletized loads using reusable cooling veins, which needed to be removed before final shipment. The existing manual process was labor-intensive, inefficient, and posed ergonomic risks to employees.

CHALLENGES:

- The company needed to optimize the palletization process to ensure proper airflow for cooling the products.

- Cooling veins are expensive, so removing them for re-use before final shipment while maintaining pallet integrity was imperative.

- The existing manual removal and repalletizing process was time-consuming, inefficient, and posed safety risks.

- The pallets varied in height and case types, requiring an adaptable automation solution.

- The system needed to integrate seamlessly with the company's existing warehouse management system.

THE SOLUTION:

To address these challenges, we designed, built, and implemented a customized robotic system to depalletize, remove and store cooling veins, and then repalletize loads in the correct order. This system fully automates the process of cooling vein removal and re-palletization in a consistent and timely manner.

KEY FEATURES:

- Automated Load Identification & Data Integration

- Forklift scanners identify incoming pallets, sending load & build data to our PLC system.

- It adjusts dynamically to ensure the correct re-palletization process based on customer requirements.

- Robotic Cooling Vein Removal & Palletization

- A high-capacity robotic arm equipped with an advanced layer-picking tool was deployed.

- The system removes layers one by one, extracting and stacking the cooling veins in the process.

- The robotic arm then repalletizes the load on the correct type of pallet with precision.

- Smart Handling for Load Variability

- The vacuum-based layer-picking tool ensures secure handling of loads, even with missing or misaligned boxes.

- A light curtain sensor system detects fallen boxes, prevents errors, and checks load heights.

- The tool incorporates compliance mechanisms to adjust for uneven loads.

- Minimized Human Intervention & Increased Throughput

- Operators only need to scan barcodes; the system handles the rest.

- The automated process eliminates manual cooling vein removal, reducing labor intensity and workplace injury risks.

- Throughput significantly increased, optimizing overall plant efficiency.

- Custom User Interface for Monitoring & Adjustments

- A real-time HMI display shows load progression, ensuring transparency and accuracy.

- Operators can visually confirm load composition and adjust re-palletization when necessary.

- The system ensures that the outgoing pallet matches customer specifications precisely.

RESULTS & BENEFITS

- Enhanced Efficiency: Automated processing significantly reduced the time required for pallet handling.

- Reduced Labor Costs: Eliminated manual cooling vein removal, freeing up workers for other critical tasks.

- Improved Safety: Minimized risk of injury from lifting heavy boxes and manual handling.

- Seamless Integration: Successfully integrated with the client's warehouse management system.

- Scalability: The system is adaptable to different pallet types and product variations.

CONCLUSION: By implementing this custom robotic palletization system, the client was able to streamline their packaging and cooling operations, significantly improving efficiency, accuracy, and workplace safety. The project exemplifies how automation can revolutionize traditional manufacturing processes, leading to higher productivity and lower operational costs.