Succeeding in the Food Packaging Industry

-

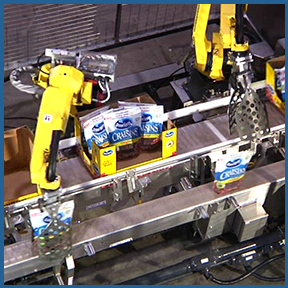

System that uses robots with clamp EOAT to pick and pack Craisins into trays.

The food packaging industry is a complex and dynamic field, facing numerous challenges in packaging, palletizing, securing, and depalletizing different food products. Each step of the process requires precision, efficiency, and adaptability to manage the diverse range of food items, from delicate fresh produce to bulky canned goods. The variation in size, weight, and material of these products necessitates diverse levels of automation, posing a significant challenge for companies aiming to optimize their packaging lines.

CHALLENGES IN FOOD PACKAGING

Packaging food products involves several intricate steps, each with its unique set of challenges. For instance, the packaging process must ensure that the food is securely wrapped, maintaining its freshness while also being appealing to consumers. Palletizing and depalletizing demand precision and care, especially for fragile items, to prevent damage during transportation. Meanwhile, securing the packaged products for shipping requires robust solutions that can adapt to assorted sizes and shapes, ensuring that the goods remain intact upon arrival at their destination.

Automation Solutions Revolutionizing the Industry

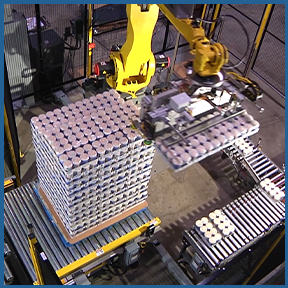

System utilizing robots with vacuum end effectors to palletize cases filled with whipped cream containers.

Automation technologies, including robotics, vision systems, and conveyor systems, have revolutionized the food packaging industry. Robotics, for example, offers versatile solutions for picking, placing, and packing diverse types of food products, accommodating varying sizes and shapes with ease. Vision systems enhance quality control, enabling real-time inspection of products for defects or inconsistencies. Conveyor systems streamline the movement of goods through the packaging line, improving speed and efficiency.

These automation systems have resulted in significant improvements in the food packaging process, including:

- Improved Precision: Automated machines can perform tasks with high accuracy, reducing errors and waste.

- Greater Consistency: Automation ensures that each product is packaged, palletized, and secured in the same manner, enhancing product quality.

- Higher Throughput: Automated lines can operate at higher speeds, increasing production rates and more effectively meeting market demands.

- Increased Profitability: By optimizing operations, companies can reduce labor costs and increase output, leading to higher profit margins.

Kaufman Engineered Systems: A Leader in Customized Automation Solutions

System utilizing robots with spatula EOAT to palletize overwrapped trays filled with plastic containers.

Kaufman Engineered Systems stands at the forefront of providing customized automation solutions to the food packaging industry. With years of expertise in designing, manufacturing, and implementing advanced automation systems, Kaufman has helped numerous clients overcome the complexities of food packaging. The company's approach involves understanding the unique needs of each client, allowing them to deliver tailored solutions that enhance efficiency, quality, and productivity.

Kaufman's success lies in its ability to leverage cutting-edge technologies and integrate them into cohesive systems that address the specific challenges of food packaging. Whether it's developing robotic palletizers that adjust to different product types or creating vision systems for meticulous quality control, Kaufman Engineered Systems consistently delivers innovation and excellence.

In conclusion, the food packaging industry is undergoing a transformation, with automation playing a pivotal role in reshaping its future. As companies strive to meet the challenges of packaging, palletizing, securing, and depalletizing food products, the adoption of automation technologies becomes increasingly vital. With leaders like Kaufman Engineered Systems driving innovation, the industry is well-positioned to achieve new heights of efficiency and profitability, setting the stage for a more productive and sustainable future.