Automated EOAT Changeover

System designed a robot that automatically detaches from one EOAT and connect to another to seamlessly switch between tasks or product size/type.

Robotic End-of-Arm Tooling (EOAT) for Precision and Efficiency in Automated Systems

In the rapidly evolving landscape of industrial automation, Robotic End-of-Arm Tooling (EOAT) stands out as a critical component that significantly enhances the functionality and versatility of robotic systems. EOAT, also called end effectors, refers to the array of devices that can be attached to the end of a robotic arm, enabling it to perform a wide variety of tasks required to efficiently pick, pack, palletize, and depalletize products of numerous types and sizes. This adaptability makes end-of-arm tools indispensable in modern manufacturing and distribution processes, where precision, efficiency, and safety are paramount.

- Improving Accuracy: end-of-arm tools equipped with sensors and vision systems can perform tasks with precision and consistency that far exceed human capabilities.

- Enhancing Productivity: Automation with EOAT operates continuously without fatigue, significantly increasing throughput.

- Reducing Costs: By automating repetitive and labor-intensive tasks, companies can reduce labor costs and minimize errors and waste.

- Increasing Safety: Robots equipped with EOAT can safely handle hazardous tasks, reducing workplace accidents.

Kaufman Engineered Systems: Pioneering Custom EOAT Solutions

Kaufman Engineered Systems specializes in designing and building custom EOAT solutions tailored to meet the unique needs of our customers. With over 40 years of experience with these tools, we have developed standard designs that we can reuse consistently for systems performing standard tasks on standard product types. We are also uniquely positioned to deliver customized end effectors for systems with unique product types or throughput requirements. Here are some of the most common EOATs we design and build for robots utilized in our systems:

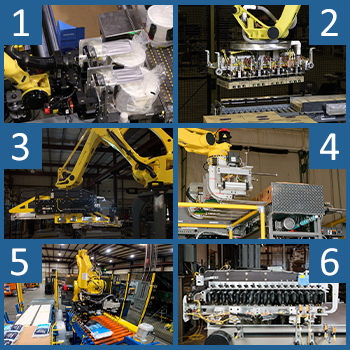

Match the picture number to the descriptions in this section.

1. Clamp Tool: an end-of-arm tool usually comprised of two metal pieces that tighten around a given item in order to lift it in the air and move it to the desired location. They are able to handle a large variety of different products/items, making them useful for many applications.

2. Vacuum Tool: This type of end effector often consists of a vacuum pump, a suction cup, and a control system. The pump creates a vacuum inside each suction cup, which in turn creates a force that allows the tool to attach to, lift, and place various types of products.

3. K5 / Sweep Drawer Tool: this is an EOAT that can be used to transfer in bulk (a full layer of bottles moved to or from a pallet rather than row-by-row) or for moving large or small cases to a specific location within a system. It’s made up of a container we call a drawer and the sweeper that moves items neatly and securely into the drawer for transport.

4. Spatula Tool: an end effector that scoops product from the bottom, lifting and then placing each load in a pre-defined location of the system.

5. Bag Tool: an end-of-arm tool that uses two rows of curved tines to close around and scoop under bags to transfer them as needed.

6. Custom Tools: this is an example of a custom tool we designed and built to pick and place layers of reverse taper wine bottles that were wider just before the neck than at the base, making it impossible for any of our standard designs to effectively move them. We call this custom EOAT a “Bladder Tool.” It has rows of deflated rubber bags that lower between the rows of bottles and then inflate to get a solid grip on the necks of the bottles so that they can be lifted and transferred securely to the desired location.

The KAUFMAN Difference

Robot with end-of-arm sweep tool to move bottles onto conveyor.

We do custom tooling, so whatever is needed, we’ll create it so that the system will do what each customer needs it to do. We have standard end-of-arm tools that we use and incorporate into our systems consistently, but we also create custom end-of-arm tools as needed to meet specific system requirements.

We build at least one end-of-arm tool for every end-of-line automation system, whether it's one of our standard or a custom EOAT; for every FANUC robot we bring in, we build the EOAT for it in-house 95% of the time. There are occasions when we will buy a tool from another manufacturer if it makes sense. For example, we had a project for a customer that needed a full-layer vacuum tool, and there was an unusual amount of detail this system required and a lot more for us to cover in building it, so, in this instance, we felt it would be more advantageous to buy this EOAT. So, if we need to outsource for any reason, we have that option as well.

The ability to customize and build these end effectors in-house gives us complete control over the outcomes for our completed systems. We control the design, and we have over 40 years of experience in designing, building, and implementing end-of-arm tools that efficiently and safely meet the required speeds and levels of throughput established by each customer for every project.

Working with Kaufman takes the risk out of procuring and implementing new automation systems because we’ve done this kind of work for so many projects over so many years. We know the longevity of each part of each end-of-arm tool; we know how each interfaces with the robot as far as ethernet and connections, how we fit pallets, and how we separate sheets. We've established a kind of tribal knowledge that we build into every part of each system we create that ensures the value and results our customers expect from us.

Partnership with FANUC Robots

Kaufman's collaboration with FANUC, a leading provider of industrial robots, further amplifies the effectiveness of our EOAT solutions. We are a Level 5 Authorized System Integrator for FANUC, the highest level of partnership they have. Our exclusive partnership with FANUC has allowed us to become experts in every make and model they provide and ensures that EOAT is perfectly matched and optimized for each and every robot we implement into our automated systems. It's a key factor in our ability to offer our customers unparalleled levels of reliability and performance in every system we design, build, and install each and every time.